sheet metal drawing operation is used to make

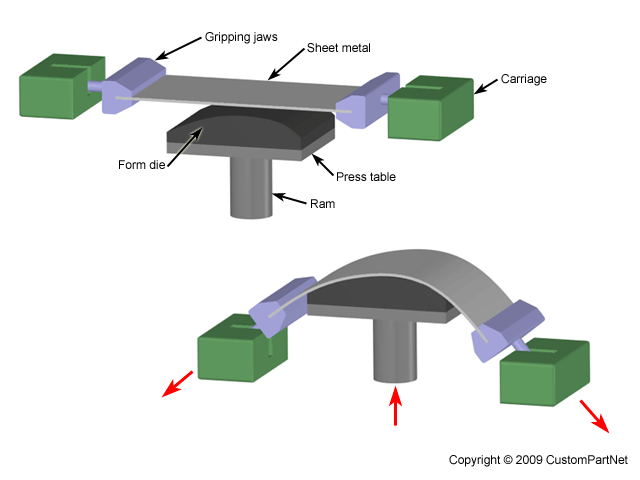

By this is meant that the materials dealt with are usually in the form. C Form height to thickness ratio To determine the minimum form height for sheet metal use the following formula.

Deep Drawing An Overview Sciencedirect Topics

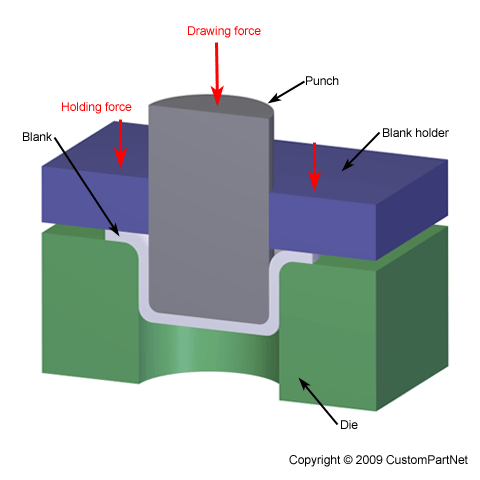

The punch-die clearance is slightly larger than the thickness of the sheet metal to be deep drawn.

. Drawing is a metalworking process that uses tensile forces to stretch metal glass or plastic. The process is typically performed cold which is done to ensure accurate tolerances better grain structure and surface finish as well as improved material properties. Metal drawing is a metalworking process by which metal is stretched and formed using tensile force.

Drawing shapes Drawing Radii. D 25T. Drawing is a metalworking process which uses tensile forces to stretch metal or glass.

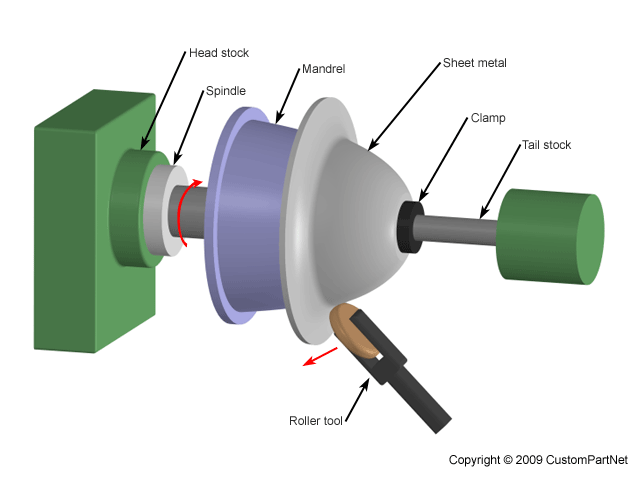

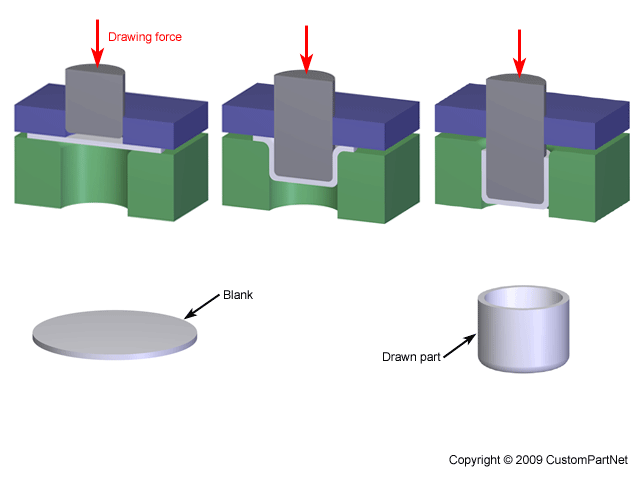

As the load applied through the punch the sheet metal is forced to. In Deep drawing operation when the force is applied by using the punch the sheet is simply pulled into the die without any shearing action and taking the shape and size same as that of. It is performed by placing a piece of sheet metal over a die cavity and then pushing the sheet into the opening with a punch.

Metal drawing often involves round profiles. Drawing is accomplished by placing a piece of sheet metal over a die cavity and then using a punch to push the metal into the cavity. As the metal is drawn pulled it stretches thinner into a desired s.

The first one is sheet metal cutting second one is sheet metal bending or forming and the last one is known as deep drawing. Mainly sheet metal process can be divided into three types. The punch is the desired shape of the base of the part once drawn.

Beverage cans ammunition shells automobile body panels. Drawing Sheet metal forming operation used to make cup shaped box shaped or other complex curved hollow shaped parts Performed by placing a piece of sheet metal over a die cavity and then pushing the metal into the opening with a punch. Most of the utensils used in the kitchen are produced by using Deep Drawing Operation only.

The die cavity matches the punch and is a little wider to allow for its passage as well as clearance. Deep Drawing Deep Drawing is a sheet metal forming operation used to make cup-shaped box-shaped or other complex-curved hollow-shaped parts. This setup is similar to sheet metal cutting operations.

In other words Piercing is a combination of cutting and forming operation. The deep-drawing process converts a sheet metal blank. To save the cost of punching or drilling in a secondary operation the following formulas can be used to calculate the minimum distance required.

Drawing is a sheet metalworking operation used to produce cup-shaped or box-shaped or other complex-curved an concave parts. As the metal is drawn it stretches to become thinner to achieve a desired shape and thickness. In addition to the specific cross sectional reduction the work material and the speed at which the product is drawn are also critical operational factors when manufacturing by metal drawing.

Drawing is classified into two types. Drawing is a sheet-metal-forming operation used to make cup-shaped box-shaped or other complex-curved and concave parts by placing a piece of sheet metal over a die cavity and pushing the metal into the cavity with a punch. As a result of the applied force from a piercing tool sheet metal starts tearing and produces an extruded hole or slot.

The die cavity matches the punch and is a little wider to allow for its passage as well as clearance. Deep drawing of sheet metal is performed with a punch and die. Sheet metal drafting is merely the application of the principles of ordinary mechanical drawing to objects which for the purposes of drawing lack thickness.

Sheet metal also known as deep drawing and wire bar and tube drawing. Introduction Cutting and forming thin sheets of metal usually performed as cold working Sheet metal 04 164 to 6 mm 14in thick. Deep drawing operation in sheetmetal is a widely used sheet metal forming Operations in the automotive and consumer goods sector to manufacture sheet metal parts.

Sheet metal drawing is defined as a plastic deformation over a curved axis. The punch is the desired shape of the base of the part once drawn. For wire bar and tube.

The term draft is used to denote the reduction in diameter of drawn round cross sections. Bending of Tube Stock. Sheet metal stampingdrawing car industry 90million cars and commercial vehicles produced worldwide in 2014.

Distance D 25T R see fig. Stamping Auto body panels 3 to 5 dies each Prototype dies 50000 Production dies 075-1 Forming dies Trimming station. Fig 1Pictorial Representation of Anvil.

Sheet metal drawing and wire bar and tube drawing. The process involves a punch with a round comer and a die with a large radius. The blank is held down flat against the die by a blank holder 25.

In this article we mainly focus on sheet metal cutting operations and other two we will discuss into upcoming articles. Piercing is a type of sheet metal punching operation used to create an extruded hole or slot in a sheet metal workpiece. Deep drawing of sheet metal is performed with a punch and die.

There are two main types of drawing. True False Coining is a bulk deformation process also used in sheet-metal work in which fine details in a die are impressed into the.

Deep Drawing An Overview Sciencedirect Topics

Key Design Principles For Successful Deep Drawing

Sheet Metal Forming Processes And Equipment Machinemfg

Die Basics 101 Fundamentals Of Drawing And Stretching

Deep Drawing An Overview Sciencedirect Topics

Deep Drawing An Overview Sciencedirect Topics

Sheet Metal Forming An Overview Sciencedirect Topics

Deep Drawing An Overview Sciencedirect Topics

Sheet Metal Tools Cutting Marking Bending Tools

Deep Drawing Find Suppliers Processes Material

9 Different Types Of Sheet Metal Operations With Diagram Pdf